FiberCell Systems Offers a Better Way to Grow Cells for Monoclonal Antibody Production, Protein Expression, and More

If you’ve worked in cell culture, you’ve surely had experience dealing with tissue culture flasks. These plastic vessels are the staple of cell culture work, but they definitely have their share of shortcomings.

Having to transfer your cells to gradually larger flasks to scale up. Carefully monitoring and changing the media. Remember to feed your cells growth factors to keep them happy. Splitting your cells to keep them from overgrowing and becoming wonky. Crying when your cells get contaminated after you split them. Worrying whether you’ve passed your cells too many times for them to be viable. Your labmate getting mad at you because you took up all the space in the incubator with your 30 T175s or your 15 rollerbottles worth of cells that you need for your experiment or protein collection.

It’s like in the infomercials when you see people opening their kitchen cabinets and becoming buried in an onslaught of mismatched storage containers and kitchenware before Billy Mays swoops in to tell you about a fantastic product that will change your life.

There’s a better way.

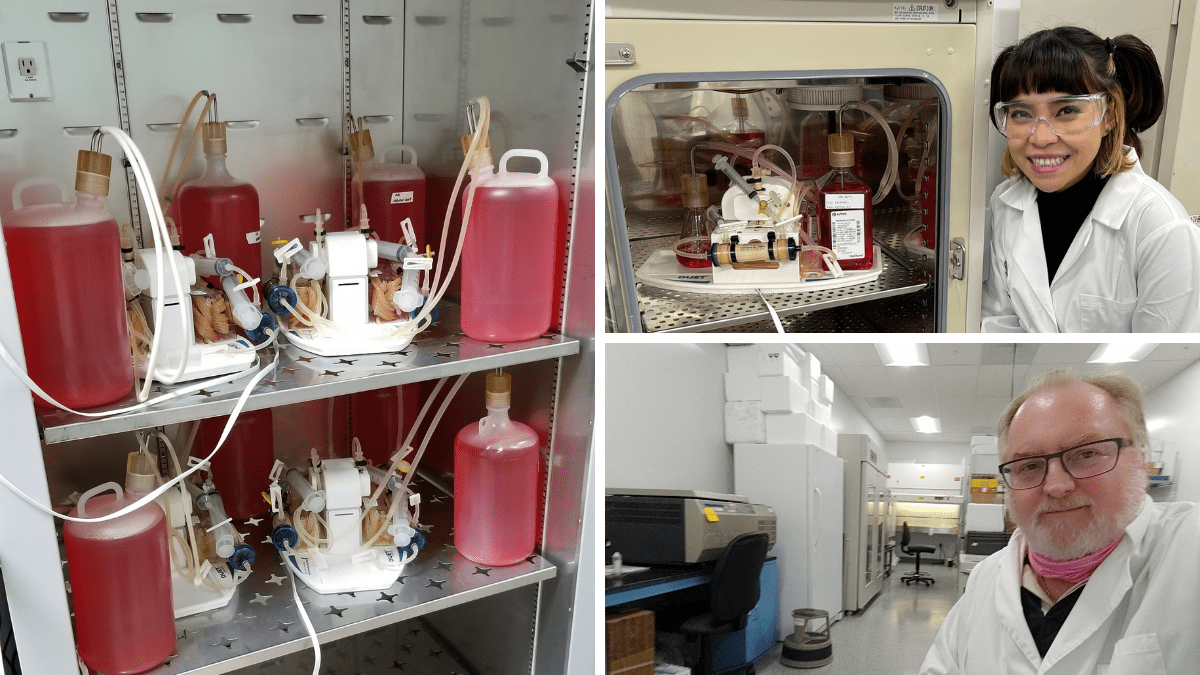

Enter FiberCell Systems – a Frederick, Maryland-based company, and member of the recently launched I-270 Innovation Labs, that is using a hollow fiber cartridge system to do cell culture better.

The cartridges are surprisingly small, but mighty. One of FiberCell’s most popular sizes, the medium cartridge, offers 4000cm2 of surface area, equivalent to about 40 T75 flasks, and can support up to 2×109 cells.

Hollow fiber bioreactors are fundamentally different from traditional cell culture methods in three important ways:

- High surface area to volume ratio. The medium C2011 cartridge has 4,000 cm2 of area in a volume of less than 20 mLs. The larger C2018 cartridge has 1.2m2 of area in a volume of 60 mLs. 200 cm2/ml means that cells can be cultured at high density, 1-2×108 cells/ml. A hollow fiber bioreactor is the only method that can support cells at in vivo like cell densities.

- Cells are bound to a porous support. Unlike 2D flasks, the cells in a hollow fiber bioreactor are bound to a porous support, much like they are in vivo. Nutrients diffuse from the bottom up, so cells are free to grow post-confluent and form 3D structures. Splitting is not required, and passage number is irrelevant.

- The Molecular Weight Cut-Off of the fiber concentrates secreted products. Small molecules like glucose and lactate can freely cross the fibers. Larger secreted products of interest such as proteins, antibodies, and extracellular vesicles cannot cross the fiber and are concentrated up to 100X in the extracapillary space of the cartridge where they can easily be harvested in a volume of 20-60 mLs.

Here are just a few of the advantages that FiberCell’s products offer to research labs and companies alike.

Simplified Handling

Think for a moment – how much time do you think you’ve spent splitting and seeding cells in new flasks for scale-up? How many weekends have you ran into the lab to take care of your cell cultures or change out media?

Talk to any cell biologist, and they’ll likely tell you that their cell cultures are like their children – requiring our constant attention because they’re needy and finicky, some with very specific nutritional needs.

With hollow fiber cartridges, you just need a small number of cells for seeding. And once the cells reach high density, they are able to create their own microenvironment that requires very little maintenance. Cell media is hooked up to the system, with conditions such as pH being precisely monitored so that you don’t have to do the guesswork to know whether your cells are happy. As such, cell cultures can be maintained continuously for months at a time (the current record is two years of continuous culture). Maintenance takes only 15 minutes a day—check glucose concentration, harvest the product with a couple of syringes, and change the medium bottle if required.

The hollow fiber systems also overcome a tricky challenge seen in cell culture and protein production – TGFbeta, which is a known growth inhibitor produced by hybridoma cells. When Cesar Milstein developed hybridoma technology, he knew that fusing a B cell with a cancer cell would create a cell that inhibited its own growth. The porous, size-selective nature of the fibers allow for TGFbeta to diffuse away, while large secreted antibody becomes concentrated in the extracapillary space.

More Similar to in vivo Conditions

Petri dishes and plastic well plates are a staple for in vitro experiments, but let’s be real – our bodies aren’t lined with plastic. In vitro can only go so far in telling us information about how a cell system behaves, and in vivo animal models can be expensive and tricky to work with, especially if you’re using them as an infection model.

Hollow fiber cartridges create a cellular environment that more closely mimics animal biology, providing researchers with better data than they likely would get from doing experiments in plastic plates.

The system can be used for a variety of applications, from PK/PD and toxicology experiments to cryptosporidium gut studies to tuberculosis antibiotic testing. In fact, Rockville-based Sanaria uses the FiberCell hollow fiber system to recapitulate the mosquito salivary gland environment to test out their malaria vaccine candidates – much easier than doing work in tiny mosquitos, and safer as well since infectious agents are contained.

Reduced Serum Dependency

Serums such as fetal bovine serum (FBS) are a staple in traditional cell culture work, supplying necessary nutrients and growth factors to cells. There are many inherent issues at hand, though, such as lot-to-lot variations and protein contamination that can muck up purification schemes.

Cells grown at high density in a hollow fiber system can be more easily adapted to serum-free and protein-free mediums. In fact, FiberCell Systems offers their own chemically defined protein-free media supplement specifically optimized for high density cultures that can be used in place of traditional serum, eliminating the need to test new lot batches or worry if your cells will behave differently when you receive a new lot. The CDM-HD media also comes as a powder that can be reconstituted, offering cost savings and easier storage.

Improved Protein Expression

If you’re looking to express proteins or antibodies, hollow fibers are the perfect choice to fit your needs. Because of the system’s superior surface area, proteins are much more concentrated vs. traditional supernatants that you would harvest, often in the range of 100-300 ug/mL/day. Cell cultures can also be maintained for several months at a time, meaning that protein production is continuous.

Another key advantage is that the microenvironment within the hollow fiber system results in improved protein folding and more uniform post-translational modifications. Scientists have even been able to express notoriously difficult proteins such as IL-15-receptor complex with tertiary structure intact.

Better for the Planet

Sustainability is a topic that is top of mind for many life sciences companies and research, which have the unfortunate reputation of generating a lot of plastic waste because many labwares need to be single-use. Petri dishes, flasks, and roller bottles are no exception.

When you use hollow fiber systems, you end up using less plastic waste overall because there is no need to continually change out flasks.

Even more, the reduced serum use is better for animal welfare. And because cells grown within the system have more in vivo-like properties, there is also potential for having to use fewer live animals in experiments.

Support Every Step of the Way

We get it – changing to a new way of doing things can be scary, especially if you work with a finicky biological system. You might be intimidated by the thought of having to optimize, or you might have reservations about whether you can actually get the system to work.

Believe it or not, hollow fibers have actually been around for a long time, and many labs across the globe have seen tremendous success using this technology.

FiberCell Systems knows this and isn’t going to leave you in the dust after you purchase. Their team of experts are ready to work closely alongside customers to help them find success. They even offer CMO services if you prefer that FiberCell does the heavy lifting for you.

FiberCell Laboratories offers complete hollow fiber bioreactor production of monoclonal antibodies from 100 mgs on up to gram scale quantities, protein production from CHO, HEK293 and BHK cells, along with extracellular vesicle production from most cell types including mesenchymal stem cells.

The company has operated from specialized space at the I-270 Innovation Labs since it became available. John Cadwell, the founder, gives credit to the facility and values the resources and partnerships they bring to the table. “The flexible lab layouts, useful shared equipment and amenities, and strategic partnerships with companies such as lab equipment and services supplier BaneBio have been super important to us. Equipment repair and testing is at the ready, and if a project comes up that requires new space, lab reconfiguration, or equipment, the I-270 Innovations Labs and BaneBio are right there to help out, often the same day. It’s an arrangement you don’t find in many places, and it’s been invaluable to FiberCell.”

Excited and ready to make a change in the way you do cell culture? Whether you’re a research lab or a business, contact FiberCell Systems to learn more and request a quote.

- About the Author

- Latest Posts

Sarah Ellinwood is BioBuzz’s Managing Editor. A scientist by training and a science communicator at heart, Sarah specializes in making complex concepts understandable, engaging, and exciting. She received her Ph.D. in molecular and cellular biology with a focus in infectious disease immunology from the University of Maryland and is passionate about all things related to scicomm, peer mentorship, and women in STEM.