Sensor Technology Developed at UMBC Set to Illuminate Bioprocessing “Black Box”

For years, bioprocessing engineers have struggled to monitor their experiments with large and expensive dissolved oxygen and pH electrodes that were impractical for ubiquitous cell culture bioprocessing tools like T-flasks and shake flasks. These electrodes lack sensitivity and cannot produce real time data outputs, lengthening the upstream development process and often keep engineers in the dark about the quality of their cell culture work until it is too late.

Dr. Govind Rao of the University of Maryland, Baltimore County (UMBC) and his colleagues at the university’s Center for Advanced Sensor Technology (CAST), recognized this bioprocessing problem and worked for decades to create an affordable, practical and reliable solution for real-time bioprocessing monitoring. Dr. Rao and his team successfully filed groundbreaking patents for optical sensors for monitoring dissolved oxygen, pH, CO2, and glucose, eventually becoming leading experts in the field.

In 1999, Dr. Rao and his colleague from the Massachusetts Institute of Technology (MIT) Dr. Joe Qualitz founded Fluorometrix Corp to commercialize their products. Fluorometrix Corp was eventually acquired by Scientific Industries (SI) and was renamed Scientific Bioprocessing, Inc. (SBI).

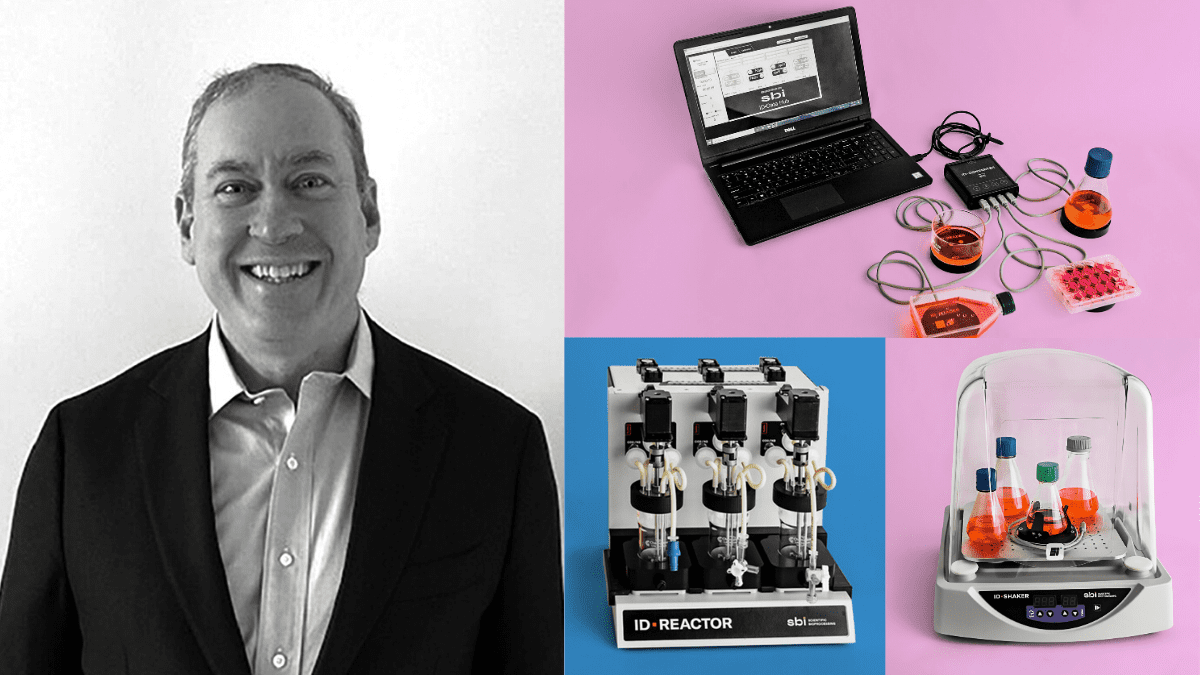

“Dr. Rao’s findings at UMBC turned the cell culture process on its head and have enabled the democratization of the use of non-invasive sensors for everyday bioprocessing. T-flasks and shake flasks are the standard process scouting devices but they are really black boxes that provide limited information to engineers. A lot of the real-time data is hidden from scientists,” stated John Moore, Chairman of Scientific Industries (SCND-OTCQX) and President of SBI.

“SBI’s sensors are transforming this black box into a real time, accurate process scouting device that can be monitored remotely,” he added.

Traditional bioprocess scouting using pH or dissolved oxygen (two important factors in cell culture bioprocessing) electrodes inserted into shake flasks can disrupt cell culture conditions, are labor-intensive, expensive, susceptible to human error, and don’t provide real-time data outputs that enable adjustments or quick “go-no-go” decisions by scientists.

SBI’s sensors are disposable, highly affordable and can be placed directly into T-flasks, shake flasks, and custom bioreactors in a variety of form factors. Sensor size is no longer an impediment to the accurate monitoring of cell culture data.

“Think of our sensors as a postage stamp that can be attached to any cell culture vessel. Outside the culture vessel is a reader the size of a hockey puck that connects directly to a computer that collects real-time pH and dissolved oxygen data. We can put sensors on almost any vessel, including organ-on-a-chip microfluidic devices, and they produce accurate, high-resolution data over long term use,” commented Dr. Sandy Williams, a biomedical engineering expert, and consultant with SBI.

“Our sensors feed into our proprietary intelligent and dynamic, ID, closed-loop system, so once we have data input, the system can control and modify cell culture conditions to create the best environment for cell growth,” she added.

SBI’s ID closed-loop system is automated and has remote-monitoring capabilities, empowering bioprocessing engineers with ultimate oversight over the cell culture process without having to come into the lab to make adjustments on nights and weekends. This remote monitoring capability is particularly important in the current COVID-19 social distancing environment.

SBI’s sensors can be deployed for cell culture processes, tissue and organ development, microfluidic devices, and the development of therapeutics, such as vaccines, antibodies and cell and gene therapies. These sensors essentially move obtaining bioprocessing insights from the end of the process to a perpetual, ongoing stream of real-time insights acquired throughout the process.

“We’ve essentially created a line of sensors that’s as good or better than electrodes and that can be easily integrated into larger bioreactor control systems. Our ID closed loop system can plug right in and be either stand-alone or fully integrated into existing automation controls and software,” stated Moore.

“Up until now, many cell culture techniques were human centric and not cell centric, or focused on the cell’s needs. We can put sensors into the hands of great scientists to unlock the mysteries of the cell. Gaining real-time insights up front during process development that reduce development timelines and costs will ultimately lower the cost to patients in need. We think SBI’s products can play a big part in that,” stated Moore.

What started in the halls of UMBC and its CAST program has generated groundbreaking patents, a stand-alone company and an acquisition that is on the verge of fundamentally transforming upstream bioprocessing. This evolution has resulted in an SBI product line that could empower a more affordable, faster, more accurate and efficient process that could significantly accelerate drug and product discovery, making life changing products more readily available and affordable for patients in need.

SBI is “powering scientific audacity”, indeed.

SBI is a strong supporter of the BioHealth Capital Region

and is offering free sensor kits to a select few biotech companies

in the region that would benefit from real-time pH and

dissolved oxygen sensing.

Contact SBI directly to express your interest.

- About the Author

- Latest Posts

Steve brings nearly twenty years of experience in marketing and content creation to the WorkForce Genetics team. He loves writing engaging content and working with partners, companies, and individuals to share their unique stories and showcase their work. Steve holds a BA in English from Providence College and an MA in American Literature from Montclair State University. He lives in Frederick, Maryland with his wife, two sons, and the family dog.