The UMD Program that Helped MedImmune develop its Best Selling Drug

Get to know The Biotech Research & Education Program at UMD

Those startups who are fortunate to make it to a clinical or commercial stage biotech company face yet another problem. It’s hard, and getting harder, to find qualified talent with industry experience; especially in the bio-manufacturing and process development space. No matter their GPA, if graduates don’t have the hands on experience it takes longer for a company to get them up to speed, which costs more money, and makes for a riskier hire.

The University of Maryland realized these common industry related problems way back in 1985 and developed a unique program to solve them. This program has been so successful that it has continued to impact innovation in the local economy for more than 30 years and helped some of the prominent names in our region, like MedImmune, Martek and Paragon Bioservices, to get started.

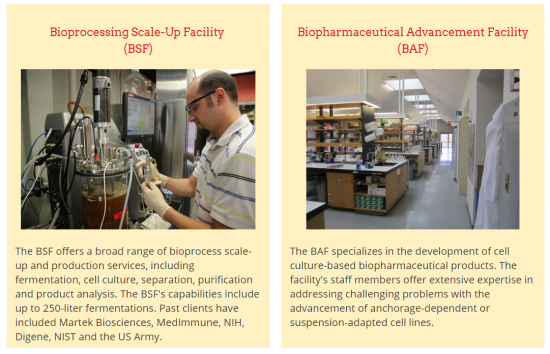

This program is the MTECH Bioprocess Scale-Up Facility (BSF) which was launched to work with companies as well as University and Federal researchers to scale-up their biotechnology products efficiently and inexpensively by using university equipment and staff, and a trained student workforce. These services immediately offered a huge benefit for the numerous UMD spin-outs and regional startups who began using them. It also built a stronger bridge between university and industry which is something that MTECH works hard to foster.

One of the most celebrated success stories which also has had the greatest impact on our region was with a small company (at the time) called MedImmune, who worked with the BSF on six jointly funded research programs – including three directly related to the company’s best-selling drug, Synagis (since 1996). MedImmune, no longer small by any definition and since acquired by AstraZeneca, just hosted 1,000 regional leaders for the BioHealth Capital Region Forum. At that forum, in MedImmune’s auditorium UMD President Yoh highlighted this achievement to showcase the great impact that innovative programs like these can have on the success of local companies and the region at large.

The President for @Univ_System_MD @presidentloh

Tells the story of the small company @MedImmune in 1996 when they started in the region but are now driving #education locally#BHCRForum18 pic.twitter.com/tEVgpt8R61— Nick van Terheyden, MD (@drnic1) April 23, 2018

The program has since expanded and is now called The Biotech Research and Education Program (BREP) which consists of two core facilities dedicated to proving supplemental research, training and consulting to academia, government and industry; (1) the Bioprocessing Scale-up Facility (BSF) at the College Park campus, and (2) the Biopharmaceutical Advancement Facility (BAF) which opened in 2010 at the Universities of Shady Grove.

BREP is run by Program Director, Ben Woodard, since 1997 who has created a culture of excellence and learning that his students and staff carry with them in their work and into their future careers. Ben’s commitment to delivering exceptional results and building lasting relationships with his clients has earned BREP the respect and trust of the hundreds of companies and researchers they have serviced across the State.

How BREP is impacting the growth of Biotech companies in the region:

Since its inception, BREP/BSF has been solving industry challenges and striving to create value for both their students and their customers, and they have a great track record to prove it. Here are some real examples of how companies have used BREP services and why.

1. Helping to launch startups & success stories.

“In the U.S. every child ten years and younger has probably consumed Martek’s molecules to improve their brain and eye development at a critical stage early on. It all started here at BSF. It all came from this facility.”

~Henry “PETE” Linsert, Former Chairman and CEO, MARTEK

With university funded facilities and staff with trained student technicians, it costs startups less to get top quality R&D and production processes that are directly transferable to partners operating under cGMPs when they are ready to further scale. Companies like MedImmune, Martek and BioFactura each utilized the BSF program to scale their technology in early years.

2. Giving small companies extra horsepower to grow.

“The Scale-Up Facility at the University of Maryland has allowed us to offer services we could not have normally. We have managed to become quite successful as a benefit of the facility.

~Marco Chacon, Former President and Founder, Paragon Bioservices

As a smaller company, partnering with BSF can give you confidence to go after some bigger clients. The BSF enables small manufacturing companies to offer extended capabilities to major pharmaceutical (Big Pharma) companies out-of-state. They become the outsourced development arm of your company that you can call on to deliver efficiently on those bigger deals when they come in.

3. Providing Workforce Training on critical skills.

“The Biomanufacturing Workshops offered by the University of Maryland exceeded my expectations. The faculty, facilitators and facilities were professional and delivered top-notch instruction. I’ll be sending additional members of my team to the workshop.”

~ Jeff Hackney, Manager of North American Life Sciences Business Development for Emerson Process Management

BREP also offers workshops on Fermentation, Downstream Processing, Cell Culture and Analytical Sciences, as well as customized trainings for companies such as MedImmune and Baxter. An expert staff with years of experience and industry relevant curriculum offers many companies a cost efficient way to upskill their bioprocessing workforce. This helps companies become more competitive and also helps them retain their key employees who may otherwise leave to get the added training and career growth at another company.

Notable BREP Clients Include:

The future of BioManufacturing Innovation with BREP

This past year BREP has been a critical component to the NIIMBL program which UM Fischell School of Engineering’s Dr. Bill Bently is a Co-PI on. This program, launched from a NIST seed fund of more than $150M, is building a national Industry-led coalition of companies, universities and states to help insure America’s competitiveness in Bio-Manufacturing. BREP was one of the first recipients of an innovation grant to develop and implement an automated bioprocess test bed, called SPIDER.

Partnering with NC State, and Worcester Polytechnic Institute, the three will create unique test beds that focus on a specific bioprocess unit operations and consist of Sensors, Process control, Integration of data, Data analysis, Evolution of the process based on data, and Reporting. The result will be a complete engineering package developed for each site so that design specifications, operating procedures, and hands-on training curricula can be utilized to advance the industry.

With such a long history of success and impact, I’m sure BREP will continue to evolve and grow, but at the core of what they do will always be solving problems for Industry and others who are interested in commercializing their ideas.

For more on how BREP can help solve your organization’s scale up or workforce challenges, contact Kevin Knapstein.

Kevin Knapstein

Manager, Bioprocess Scale-Up Facility

Tel: 301.314.7806

[email protected]

- About the Author

- Latest Posts

Over the past 11 years, Chris has grown BioBuzz into a respected brand that is recognized for its community building, networking events and news stories about the local biotech industry. In addition, he runs a Recruiting and Marketing Agency that helps companies attract top talent through a blended model that combines employer branding and marketing services together with a high powered recruiting solution.